Solve Your Aerodynamic Challenges With Precision

From initial assessment to production-ready design, we combine advanced CFD simulation with systems-level problem-solving.

Complex flow behavior slows innovation. Whether you’re optimizing design, reducing drag, understanding unsteady effects, or planning validation tests, aerodynamic decisions shape performance, emissions, and safety. We solve these challenges analytically, first understanding your problem, then choosing the right methods to deliver tangible results.

Schedule a 15-30 minute conversation. Discover what aerodynamic optimization can do for your product.

Aerodynamic Challenges We Solve

You’re designing a new product with complex flow behavior. Maybe you need to optimize geometry for efficiency, reduce drag on a vehicle or any structure, or understand unsteady aerodynamic effects. Or perhaps you’re planning wind-tunnel tests and need CFD validation to guide experimental work. Whatever the challenge, precision matters. The difference between a mediocre and optimized design often comes down to rigorous aerodynamic analysis, and translating that analysis into engineering decisions that work in the real world.

Design Concept

- Defining aerodynamic concepts for specific mission requirements

- Understanding how geometry changes affect flow behavior

- Predicting performance across operating conditions

Why it matters: Right concept at the start saves months of iteration later

Flow Optimization

- Drag reduction through geometry optimization

- Flow efficiency improvements (lift-to-drag, pressure recovery, etc.)

- Cooling and ventilation flow

- Multi-objective optimization (Minimize drag AND noise, Balance aerodynamics with structural constraints)

Why it matters: 5-10% performance gain often justifies entire optimization study

Unsteady Aerodynamics

- Time-dependent flow phenomena (blade-wake interactions, vortex dynamics)

- Periodic force oscillations and their influence on design

- Understanding complex flow behavior at off-design conditions

Why it matters: Unsteady effects often become the design constraint

Aero-Thermal interaction

- Engine nacelle and propulsion cooling

- Electronics and battery thermal management

- Environmental control systems

- Multi-physics CFD coupling: Integrated aerodynamic and thermal simulation

Why it matters: Thermal management determines system limits

Test Planning & Validation

- Wind-tunnel test planning and guidance

- Flight test preparation and correlation strategy

- CFD-to-experiment validation workflows

- Bench test planning for aerodynamic rigs

Why it matters: Well-planned tests reduce cost and schedule

Certification & Safety Support

- Aerodynamic inputs for loads and structural analysis

- Flight envelope validation and margins

- Performance demonstration for regulatory approvals

Why it matters: Aerodynamics are often the design constraint in certification

Our Three-Phase Approach

Every project is different. Some start with a well-defined problem, others need clarification first. Our process is flexible, but always follows the same principle: understand deeply, analyze rigorously, deliver actionable results.

1. Rapid Assessment

What Happens:

- Problem clarification

- Analytical scoping

- Method selection

- Preliminary findings

Deliverable: Assessment report with problem summary, recommended approach, feasibility assessment, and next steps.

Timeline: 5-10 working days

Why Start Here? Low barrier to entry. You prove the partnership works before committing to larger engagement. Many clients discover quick wins here.

2. Detailed Analysis

What Happens:

- Detailed problem setup

- CFD/analytical modeling

- Iterative refinement

- Design recommendations

Deliverable: Comprehensive technical report with methodology, CFD results, design recommendations, test roadmap, and risk assessment.

Timeline: 1-6 months typically, up to 1 year

Why Phase 2 Matters? This is where optimization happens. Where simulation informs design. Where precision drives results.

3. Validation

What Happens:

- Test correlation

- Certification support

- Troubleshooting

Deliverable: Validated designs, test reports, design inputs to other teams, regulatory compliance summaries.

Timeline: As needed (ongoing)

Why This Phase? Simulation is only valuable if validated against reality. This phase closes the loop.

Our Tools & Expertise

We’re tool-agnostic. We assess what’s best for your problem, not what we’re comfortable with. Here’s what we bring to the table among other softwares:

OpenFOAM

Open-source CFD

Our primary choice for flexibility and control

ANSYS Fluent

Commercial CFD (on demand)

Most comprehensive, robust, and well‑integrated general‑purpose tool

Star CCM+

Commercial CFD (on demand)

Most integrated, automated, and productive CFD platform

ProLB

Comercial lattice boltzmann method (on demand)

Extremely powerful for unsteady simulations.

Custom Scripts

MATLAB/Python for optimization, data processing, automation

CAD Integration

CATIA , Salome, and CAD-to-CFD workflows

Technical Capabilities

- Design Concept Development — Aerodynamic design from first principles, trade-space exploration, parametric optimization

- Flow Optimization — Design space exploration, multi-objective optimization, automated workflows

- Unsteady Aerodynamics — Time-accurate simulations (URANS, LES), blade-wake interactions, complex flow analysis

- Test Planning & Validation — Wind-tunnel guidance, flight test planning, CFD correlation

- Certification & Regulatory Support — Performance documentation, envelope validation, safety margins

- Cross-Domain Expertise — Aero-thermal coupling, aero-structural interaction, manufacturing constraints

Why Choose Privilege Aircrafts

Senior Expertise Directly Accessible

You work with a senior engineer, not a junior analyst. 15+ years in aerospace R&D (ONERA, Airbus, Snecma, Flying Whales) means I understand aerodynamics at depth, know what works in practice, and can make judgment calls fast. Direct access. No account managers. Just an engineer who listens, analyzes, and delivers.

We've Shipped Real Products

We don't just analyze, we've optimized manufacturing processes, designed commercial products, and commercialized proprietary technology. We understand the constraints: cost, manufacturability, certification, safety, time. Our aerodynamic recommendations don't just look good on paper. They work in the real world.

Speed Without Compromise

Small firm = no protocols overhead. No weeks of internal approvals. No hand-offs between departments. You get quick decisions and rapid turnarounds (days for assessments, weeks-to-months for detailed studies). And we don't sacrifice rigor for speed. Aerospace-grade precision, delivered fast.

Proven Expertise: Real Projects, Real Results

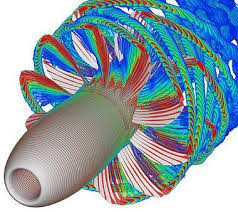

Counter-Rotating Open Rotor (CROR) Development for Airbus

The Challenge

Airbus was developing next-generation counter-rotating open rotor (CROR) engines to meet aggressive fuel economy and CO2 reduction for future commercial aircraft. The challenge: optimize blade geometry to maximize propulsion efficiency while minimizing noise to acceptable levels.

Context: I was part of the French research team contributing advanced CFD analysis and design optimization to this major European aerospace initiative.

Our Approach

- 3D URANS CFD modeling of blade interaction

- Multi-objective optimization across flight envelope

- Design optimization with structural/manufacturing constraints

- Validation vs. rig test data

- Coordination with international research teams

The Outcome

- Optimized blade designs with improved efficiency

- Maintained structural margins and constraints

- CFD validated against experimental data

- Contributed to Airbus’s strategic research roadmap

Airship Ventilation

Client: Flying Whales (French Tech Next 40)

The Challenge

Design an efficient ventilation and cooling system for a large helium-filled cargo airship operating under extreme conditions. The unique challenges included:

- Low flight speeds — Minimal convective cooling from airflow

- Heat-sensitive envelope — Textile materials with strict temperature limits

- Solar radiation loads — Large surface area exposed to solar heating

- Multi-physics coupling — Complex interaction between aerodynamics, thermal radiation, convection, and structural constraints

Our Approach

- Advanced thermal modeling — Implemented TAITherm and ProLB simulations on AWS infrastructure to predict helium behavior and envelope heating

- Material characterization — Conducted detailed analysis of radiative properties for envelope materials and helium cell fabrics

- Flight simulator integration — Contributed thermal behavior models to the flight dynamics simulator for pilot training

Results & Impact

✓ Material selection guidance — Identified optimal combination of envelope materials and helium cell fabrics based on thermal performance

✓ Accurate thermal prediction — Developed highly precise thermal model accounting for real-world solar radiation and convection phenomena

✓ Operational confidence — Enabled accurate prediction of airship thermal behavior under diverse flight conditions

Key Differentiator: This project required deep understanding of both aerodynamics and thermal physics. Few consultants can integrate these disciplines effectively for such unconventional applications.

FAQ

What is typical timeline?

Phase 1 (Rapid Assessment): 1-2 weeks

Phase 2 (Detailed Analysis): 1-6 months typically; can extend up to one year for complex, multi-phase projects with multiple design iterations

Phase 3 (Ongoing Support): As needed, typically ongoing during test or design iteration

Many projects run parallel phases: we’re running Phase 2 analysis while you’re preparing Phase 3 validation tests

Can you work with our existing simulation tools?

Yes. We’re tool-agnostic:

- If you have ANSYS Fluent licenses, we can use those

- If you prefer OpenFOAM (open-source), we’ll use that

- If you have your own in-house codes, we can integrate with them

- If you need a new tool, we recommend the best fit for your problem and help with setup

We assess what’s best for your problem, not what’s convenient for us.

What if we have limited time and resources?

Start with Phase 1. It’s quick (5-10 working days) and lets you:

- Understand your problem better

- Get a recommendation for the right approach

- Test the partnership with Privilege Aircrafts

- Build internal buy-in for Phase 2 if results are compelling

Many clients discover that Phase 1 solves their immediate question. Others use it to justify Phase 2 investment.

Do you offer smaller projects or targeted consulting?

Yes. If you need:

- Technical review of existing CFD results

- Design guidance on a specific problem

- Second opinion on an analysis approach

- Short technical workshops for your team

We can structure these as focused consulting engagements.

How do you handle proprietary and confidential information?

Complete confidentiality:

- We sign NDAs covering your technology, designs, and results

- Analysis results and recommendations are your intellectual property

- We never discuss client work or results without explicit permission

- Any publications or case studies require your written approval

Can you work across industries, not just in aerospace?

Yes. Fluid mechanics principles are universal:

- Aerospace: Aircraft, drones, helicopters, engines, parachutes

- Marine: Hydrodynamic design, propeller optimization, hull optimization

- Energy: Wind turbines, hydro turbines, solar thermal systems

- Architecture: Building aerodynamics, wind comfort, natural ventilation

- Automotive: Aerodynamic drag, cooling airflows, thermal management

- Medical/Industrial: Flow in ducts, heat exchangers, specialized applications

What we bring (rigorous analysis, optimization, validation) applies everywhere fluid mechanics matters.

Schedule a 15-30 minute conversation. Discover what aerodynamic optimization can do for your product.