Turn Thermal Challenges Into Performance Advantages

From overheating batteries to inefficient cooling systems, we transform thermal constraints into competitive advantages through advanced simulation and innovative solutions.

Thermal limits kill performance. Overheating shortens battery life, throttles processors, reduces solar efficiency, and constrains design. But thermal management done right unlocks 20-30% performance gains, extends product lifetime, and cuts energy costs dramatically. We solve thermal problems with deep physics understanding, advanced simulation tools, and innovative cooling strategies, delivering validated solutions that work in the real world, not just in reports.

Schedule a 15-30 minute conversation. Discover what thermal optimization can do for your product.

Thermal Challenges That Limit Performance

And How We Solve Them

You’re designing a system where thermal behavior determines success or failure. Maybe your EV batteries overheat during fast charging. Your data center hits thermal limits and throttles performance. Your solar thermal system underperforms. Or perhaps thermal constraints force you to compromise on weight, size, or power. Whatever the challenge, thermal optimization isn’t optional, it’s your competitive advantage. We combine deep thermal physics understanding with advanced simulation to unlock performance others can’t achieve.

Battery Thermal Management

EV battery pack thermal design

Fast-charging thermal strategy

Thermal runaway prevention and safety analysis

Battery Management System (BMS) thermal integration

Second-life battery thermal characterization

Thermal testing strategy and validation

Why it matters: Battery life, safety, and fast-charging capability all depend on thermal management. Poor thermal design = reduced range, warranty failures, and safety risks. Proper thermal optimization = 20% longer battery life and safe fast-charging.

Aerospace Propulsion

Engine thermal management

Avionics and electronics cooling in harsh environments

High-altitude and extreme-temperature thermal behavior

- Thermal management in space

Lightweight thermal insulation and heat shielding

Cabin environmental control and thermal comfort

Why it matters: Aerospace thermal challenges are unforgiving—altitude, speed, and temperature extremes demand precision. Our aerospace heritage means we understand that “good enough” isn’t good enough.

Data Center & HPC

AI processor thermal management

Liquid cooling system design (direct-to-chip, immersion)

Two-phase cooling optimization for maximum efficiency

Hybrid air-liquid cooling strategies

Energy-efficient cooling architecture

Why it matters: AI workloads generate extreme heat. Traditional air cooling hits physical limits at 70 kW/rack. Advanced liquid cooling can handle 200+ kW/rack while cutting energy costs 30-40%.

Solar Thermal & Renewable

Solar thermal collector efficiency optimization

Photovoltaic panel temperature management (every 1°C = 0.5% efficiency loss)

Concentrated Solar Power (CSP) receiver thermal design

Thermal energy storage system optimization

Heat recovery and waste heat utilization

Seasonal thermal storage modeling

Why it matters: Solar thermal efficiency directly drives ROI. Proper thermal design = 15-25% yield improvement, faster payback, and better grid integration.

Advanced Materials & Thermal Property Characterization

Composite and textile laminate thermal conductivity measurement

Radiative property characterization

Phase-change material (PCM) thermal modeling

Anisotropic material thermal behavior

High-temperature material thermal validation

Why it matters: Accurate material properties are the foundation of reliable thermal predictions. Generic database values = massive errors. Measured properties = confidence in your thermal design.

Multi-Physics Thermal Integration

Aero-thermal coupling (airflow + heat transfer)

Thermo-structural analysis (thermal stress, thermal expansion)

Electro-thermal simulation (Joule heating, power electronics)

Radiation-convection-conduction coupled problems

System-level thermal architecture

Why it matters: Real thermal problems don’t exist in isolation. Ignoring coupling results in wrong answers. Multi-physics modeling gives accurate predictions and optimized systems.

Our Three-Phase Approach

Every project is different. Some start with a well-defined problem, others need clarification first. Our process is flexible, but always follows the same principle: understand deeply, analyze rigorously, deliver actionable results.

1. Rapid Assessment

What Happens:

Thermal problem scoping and constraint identification

Hand-calculation thermal estimates

Feasibility analysis and thermal margin assessment

Tool and method selection

Quick-win identification

Deliverable: Thermal assessment report with problem summary, thermal estimates, recommended approach, and feasibility analysis.

Timeline: 5-10 working days

Why Start Here? Many thermal problems can be solved or scoped analytically in days. You get fast answers, identify quick wins, and decide if detailed simulation is justified. Low cost, high value.

2. Simulation & Optimization

What Happens:

High-fidelity thermal model development (geometry, materials, boundaries)

Multi-physics simulation (conduction, convection, radiation, coupled)

Parametric studies and thermal optimization

Design iteration and trade-off analysis

Thermal margin verification and sensitivity analysis

Deliverable: Comprehensive thermal analysis report with methodology, simulation results, thermal maps, design recommendations, and test validation roadmap.

Timeline: 1-6 months typically, up to 1 year

Why Phase 2 Matters: This is where thermal innovation happens. Where advanced simulation reveals non-intuitive solutions. Where you discover the 20-30% performance gain hiding in your thermal design.

3. Validation

What Happens:

Thermal test planning (thermocouples, IR imaging, chamber testing)

Test-to-simulation correlation and model calibration

Design iteration based on test results

Thermal certification documentation

Production thermal troubleshooting

Deliverable: Validated thermal designs, test correlation reports, thermal compliance documentation, design inputs to manufacturing.

Timeline: As needed (ongoing)

Why This Phase: Simulation without validation is never certainty. We close the loop, proving your thermal design works in reality, not just in software.

Tools & Expertise

We’re tool-agnostic thermal problem-solvers. We choose the best simulation approach for your specific challenge, from analytical methods to cutting-edge multi-physics CFD. Here’s our thermal engineering arsenal from open source to commercial software that we employ on demand:

TAITherm

Industry-leading thermal analysis platform for aerospace and automotive, transient radiation, solar loads, complex view factors

SimScale

Cloud-based thermal simulation for rapid iteration, collaboration, and parametric studies

OpenFOAM/ ANSYS Fluent/ STAR-CCM+/ COMSOL Multiphysics

Coupling CFD with thermal analysis tools to account for all heat transfer modes.

Ansys Icepak

Electronics Cooling & PCB Thermal Simulation and Analysis

Custom Scripts

MATLAB/Python thermal scripts for hand calculations, optimization, parametric studies, and automation

CAD Integration

CATIA , Salome, and CAD-to-thermal workflows

Technical Capabilities

Conduction Analysis — Steady-state and transient heat transfer in solids, composites, layered structures, anisotropic materials

Convection Modeling — Natural and forced convection in enclosures, channels, complex geometries; turbulence modeling (RANS, LES)

Radiation Heat Transfer — Solar loads, infrared exchange, view factor calculation, participating media, high-temperature radiation

Conjugate Heat Transfer — Coupled fluid-solid thermal analysis with interface heat transfer

Phase Change Modeling — Melting, solidification, sublimation; phase-change materials (PCM) for thermal storage

Multi-Physics Coupling — Aero-thermal, thermo-structural, electro-thermal, fluid-structure-thermal interaction

Thermal Comfort Analysis — PMV/PPD metrics, thermal comfort zones, HVAC performance

Battery Thermal Modeling — Cell-level and pack-level thermal behavior, thermal runaway simulation, cooling strategy optimization

Material Property Testing — Thermal conductivity, specific heat, emissivity/absorptivity measurement; inverse modeling

Thermal Optimization — Multi-objective optimization (minimize temperature, minimize weight, maximize efficiency)

Test Correlation & Validation — Thermocouple data analysis, IR thermography correlation, thermal test planning

Certification Support — Thermal analysis documentation for FAA, EASA, automotive standards, battery safety standards

Why Choose Privilege Aircrafts

Most thermal consultants run software. We solve thermal problems. 15+ years of aerospace thermal experience means we understand the physics deeply, recognize non-intuitive solutions, and deliver validated results, not just colorful temperature plots.

Deep Thermal Physics Understanding & Innovative Solutions

We don't just model heat transfer—we understand thermal physics at a fundamental level. Aerospace thermal challenges (re-entry heating, solar radiation at altitude, cryogenic fuels, extreme temperature gradients) demand deep understanding. That expertise translates to innovative solutions for your thermal problems: novel cooling strategies, lightweight thermal management, and multi-physics optimization that generic thermal consultants miss. You get solutions that work, not just simulation reports.

Proven Track Record Solving Complicated Thermal Problems

We've solved thermal challenges others could not: helium airship thermal management (where convection fails and radiation dominates), unconventional nacelle cooling with extreme weight constraints, solar-loaded textile structures. We've led thermal team for French Tech Next-40 company and contributed thermal analysis to major aerospace programs (Airbus, Sabena Technics Flying Whales). Our thermal recommendations don't just look good on paper, they enable product launches and certifications.

Fast, Flexible, Senior Expertise

Small firm translates to fast decisions. No procurement bureaucracy. No hand-offs to junior engineers. You work directly with a senior thermal engineer (15+ years aerospace and R&D) who understands your constraints: cost, time, safety, certification. We deliver rapid assessments in days, detailed studies in weeks-to-months. And we don't sacrifice rigor for speed. We deliver aerospace-grade precision with startup agility.

Real Thermal Challenges, Innovative Solutions, Proven Results

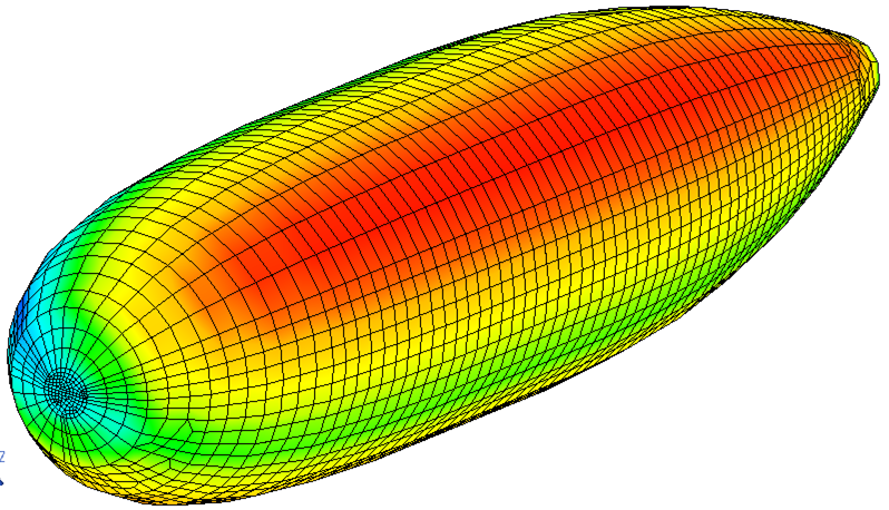

Helium Airship Thermal Management

Client: Flying Whales (French Tech Next 40)

The Challenge

Design efficient ventilation and thermal management for a large helium-filled cargo airship operating under extreme solar radiation. This wasn’t a conventional aerospace thermal problem—it required fundamentally new thermal thinking:

Variable low speeds (0-70 km/h) — Convective cooling unreliable

Massive solar loads — 25,000+ m² envelope exposed to radiation

Heat-sensitive textiles — Technical fabrics with strict temperature limits

Helium expansion behavior — Helium expands differently than surrounding air, creating structural loads; precise temperature estimates crucial for structural integrity and buoyancy control

Lightweight constraints — Every kilogram of thermal insulation reduces payload capacity

Our Approach

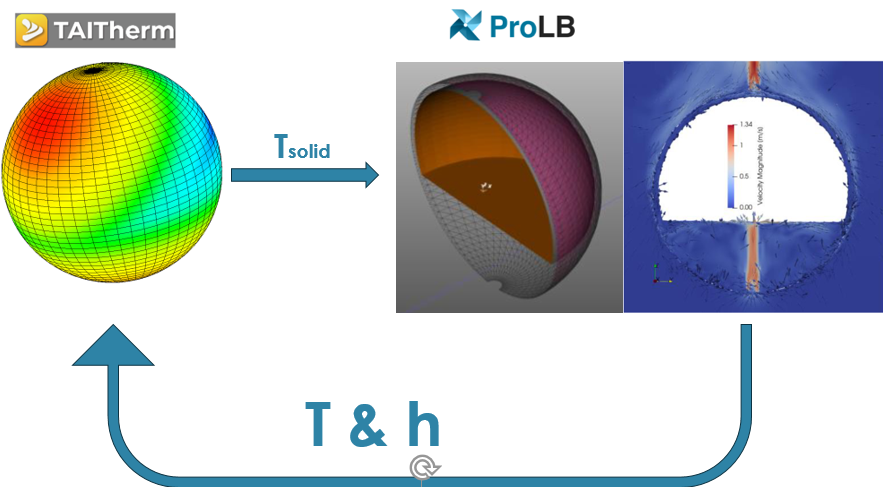

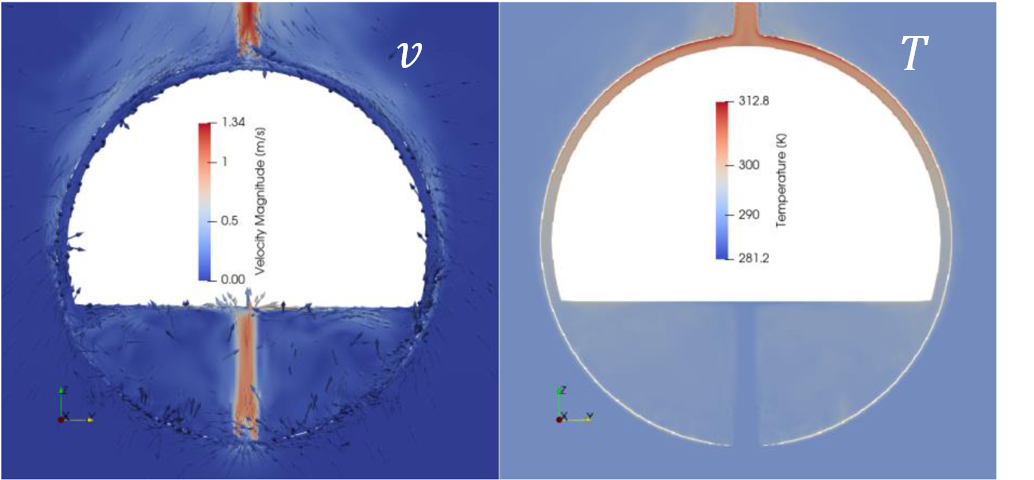

Advanced thermal modeling — TAITherm coupled with ProLB simulations on AWS; high-fidelity solar radiation model

Material characterization — Analyzed envelope and cell materials to identify optimal radiative properties (absorption, reflection, transparency) for thermal performance

Airship thermal behavior modeling — Performed high-fidelity simulation studies to predict thermal behavior across diverse mission conditions

Flight simulator integration — Contributed validated thermal models to flight simulator for pilot training and certification, accounting for day/night thermal cycles and operational conditions

Results

✓ First accurate thermal model for large helium airships — Predictions within 0.5°C of test data

✓ Structural safety enabled — Precise helium expansion predictions prevents cells overstress

✓ Material selection and optimization — Identified optimal envelope and cell materials balancing thermal performance with cost-effectiveness and operational requirements

Key takeaway: This required deep radiation physics understanding, helium thermal behavior modeling, custom textile characterization, and aero-thermal coupling at variable speeds. If we can solve this unconventional challenge, we can solve yours.

Schedule a 15-30 minute conversation. Discover what thermal optimization can do for your product.